WS 7110/1.4571 | WS 7110/3822, 3825,7550 | WS 7110/1.4571/3822, 3825,7550

The pharmaceutical-chemical industry requires low permeation for sealing applications, high chemical resistance, sturdy mechanical resilience and easier processability. TFM™, a PTFE of the second generation, has proven itself. The particles melt more easily into a dense, low pore polymer structure due to the more homogeneous crystalline structure as a result the tightness is significantly improved. High quality 3M™ Dyneon™ TFM™ is used for the envelope gaskets.

PTFE envelope gaskets combine the positive characteristics of TFM™-material with the mechanical behavior of the relevant inserts and have a very high chemical resistance. The positive

characteristics are completed with a sturdy diffusion barrier at the inner diameter of the gasket and are optimized across the entire

gasket diameter with regards to diffusion. This combination gasket is therefore used for a wide range of applications.

The graphite sheet SIGRAFLEX® was developed specifically for use in PTFE-coated non-metallic gaskets, which as a nonmetallic insert ensures an ideal interplay of the already outstanding characteristics of the individual components. There is a significant improvement of the sealing technological properties of the PTFE-envelope gaskets thanks to the good recovery property of the graphite, the stainless steel foil insert close to the

surface and the combination of the individual layers without adhesives. SIGRAFLEX® is a multi-layer sealing sheet made from flexible graphite foil which is reinforced with two 0.05mm thick stainless foils.

SIGRAFLEX® is made in sheet thicknesses of 2.0mm and 3.0mm and consists of two 0.5mm thick outer and one 1.0mm or 2.0mm thick inner layers of flexible graphite with the density of 1.1g/cm³. The compound is made without adhesive using a special process and corresponds therefore to the highest requirements with regards to strength even at high temperatures.

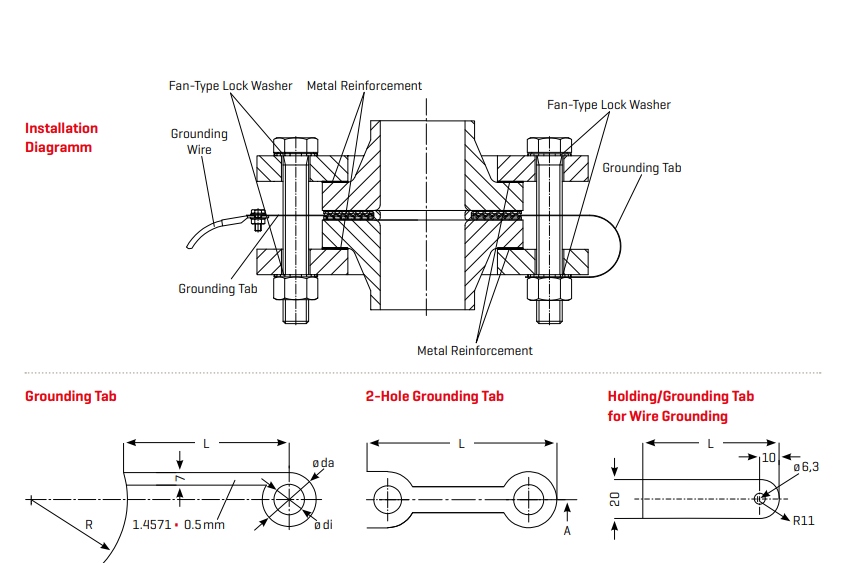

The grounding of a plant can be obstructed by insulating components such as gaskets or insulating operating materials like greases. The remaining conductive components have to be connected to each other and grounded when using insulating materials such as spacers made from plastic with high resistance. Alternatively, it is possible to ground every plant part individually. In this environment it is particularly important to consider parts which are not visible from the outside, such as: Ball valves with insulating gaskets or also metal inserts in gaskets.