Description

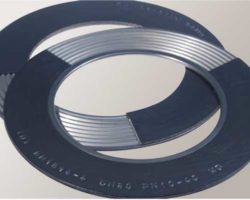

The IDT-corrugated metal gaskets consist of a corrugated stainless steel carrier with a height of s = 1.5mm and a graphite layer

of 0.8mm on both sides. Carrier profile, thickness and density of the layer are adjusted in such a way that a peak overlap of 0.1 to 0.2mm is ensured in tensioned condition at standard compression and therefore only a very low diffusion cross-section is present. Furthermore, the non-metallic material is very highly

compressed in these areas.

A partition of 3 to 4mm, a sheet thickness of 0.5 and a non-metallic layer thickness of 0.8mm has proven to be the ideal

design and is used as a standard by established plant operators. The IDT-corrugated ring is manufactured across all

nominal widths with a partition of 3 mm. If the corrugated ring is partitioned too much, then it loses in strength and has the effect that the proper function could not be achieved or could not be achieved fully and that that the mechanical characteristics and leakage related parameters are influenced negatively. The gasket has already a very good tightness at low

surface pressures and is suitable for use in existing systems due to its good mechanical characteristics. The gasket can be manufactured in various shapes such as circular, oval, long oval and frame. Transport and handling limit the maximum

dimensions [approx. 5000mm]. Cross pieces [at least 8mm wide], retaining brackets and bolt holes can be integrated. Special welding processes ensure a high welding seam quality and prevent the susceptibility to corrosion in stainless

steel carriers for very large, corrugated metal gaskets. The corrugated carrier can be covered either fully or partially with

graphite on both sides. The construction with inner eyelet excludes interference of the operating media caused by the graphite layer and also excludes interference of the sealing system caused by the operating media.